Assisting : Dividing, Feeding, Drying and Pelletizing samples

RETSCH instruments from the “Assisting” group optimize and support sample preparation with our mills, jaw crushers and sieve shakers. They provide reproducible processes with greater efficiency and are characterized by their ease of handling.

Sample dividers: RETSCH supplies sample dividers as rotating dividers and sample splitters. They divide all pourable solids so accurately that the characteristic composition of each fraction of the sample corresponds exactly to that of the original bulk sample.

1 - Sample divider: The rotating tube divider like PT 200 is the prerequisite for dust-free division and volume reduction of larger bulk samples. It is suitable for powdered or granular bulk materials. The slot width adjusts the ratio of the fractions and therefore the amount of sample.

2 - Rotating sample divider: The rotating sample divider PT 600 is specially designed for representative, dust-free division and volume reduction of large amounts of powdered or granular bulk materials. The selection of different dividing modules determines the dividing ratio and the sample amount.

.png)

3 - Sample splitter: The RT 100 is equipped with a feed hopper with closed outlet. Thus, up to 30 l sample material may be evenly spread over the entire width of the hopper. The outlet is opened manually by moving a lever and the sample is splitted. The slots of the dividing head can be adjusted to a maximum width of 108 mm.

The sample splitters RT are ideal for the on-site reduction of sample material. They are easy to use, easy to clean and do not need an electrical power supply.

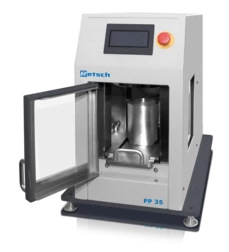

RETSCH offers three models of pellet presses with different pressure forces for the preparation of solid and smooth pellets suitable for XRF analysis.

1.PELLET PRESS PP 25

A detailed overview and knowledge of the characteristics of a raw material is of utmost importance, especially when planning the layout of a crushing plant. In order to minimize all possible risks extensive trials are necessary to obtain information on the properties of the raw materials. A clear definition of the required crushing capacities and the desired product quality can be precisely determined by using the Bond Index test methods. Using the Bond Index test procedures it is possible to calculate crushing / abrasion behavior of mineral samples. This knowledge is essential to define the required ball mill layout and production capacity.

The Bond Index conforming ball charge consists of:

The Bond Index conforming rod charge consists of:

Dryers

The fluid bed dryer TG 200 is used in quality control, sample preparation and R&D departments. It permits the gentle drying of organic, inorganic, chemical or pharmaceutical bulk materials without localized overheating. Suitable materials can be coarse, fine, crystalline, fibrous or leafy. The powerful fan of the fluid bed dryer ensures optimal air throughput so that the products to be dried are loosened up and thoroughly mixed resulting in short drying times. With the interval operation the fluidized bed is mixed even better. Temperature, drying time and air volume can be set digitally and adjusted continuously.

Feeders

The vibratory feeder DR 100 is used for the uniform, continuous feeding and conveyance of pourable bulk materials and fine powders. The DR 100 feeds RETSCH mills, sample dividers, and particle measuring devices, and it is also suitable for other feeding tasks. Its performance, adaptability and compact design makes this device suitable for a great variety of applications. The DR 100 can also be driven and controlled externally via the built-in interface. RETSCH vibratory feeders guarantee reproducibly exact results and maximize the efficiency of downstream laboratory and testing devices.

Cleaners

The ultrasonic bath range UR includes three sizes for cleaning test sieves and grinding tools quickly and easily. UR 1 is for test sieves up to 203 mm dia., UR 2 for test sieves up to 450 mm dia., and the UR 3 for the simultaneous cleaning of up to 5 test sieves 200/203 mm dia. The gentle yet thorough cleaning of test sieves in an ultrasonic bath increases their working lives as damage which could occur during manual cleaning is avoided.

.png)